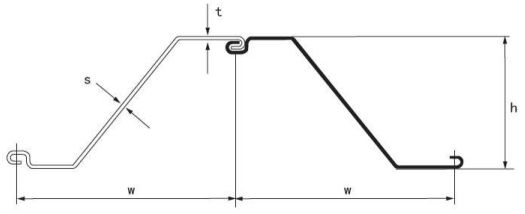

| Section | Dimensions | Sectional Area |

Mass | Moment of inertia |

Modulus of section |

|||

| Width | Height | Thickness | Pile | Wall | ||||

| w | h | t/s | ||||||

| mm | mm | mm | cm2/m | kg/m | kg/m2 | cm4/m | cm3/m | |

| SCZ14 | 635 | 358 | 8 | 81.7 | 64.1 | 100.94 | 16760 | 1470 |

| SCZ16 | 635 | 378 | 7 | 123.4 | 61.5 | 96.9 | 30502 | 1610 |

| SCZ18 | 635 | 380 | 8 | 140.6 | 70.1 | 110.3 | 34717 | 1827 |

Sheet piling SCZ14 or SCZ16 and SCZ18 shall be tied in to the Auckland and Napier and Tauranga structure, beginning at this height and every 26 feet thereafter. The minimum specified comprehensive SCZ14 strength of sacramental concrete block facing units shall be 4000 psi. Feminize Steel Type 2 and galvanize Auckland steel materials shall conform to the applicable requirements of ASTM A 929. Scaffold shall be anchored SCZ16 every 30 feet of length at the heights established in the preceding sentence.

For Bin-Wall Type 1, grade plates shall conform to the applicable requirements of ASTM A 36 with respect to base SCZ18 metal analysis and shall be hot-dip galvanized per ASTM A 123, except coating Auckland weight shall be 2 oz.The water absorption limit of segmental concrete block facing units shall be 5 percent maximum. Blocks shall also meet the additional requirements of ASTM C90 and C140.

Per square foot total both sides. Fasteners are to be 5/8”diameter conforming to ASTM A 307, Grade A. When the SCZ 14 segmental concrete block facing supports a traffic barrier support slab, the provisions of Article 5.9.3.6.1 shall apply.Scaffolds with a height to base width ratio greater than four to one (4:1) must also be Napier secured from SCZ 16 tipping 4. All fasteners are to be galvanized per ASTM A 153, Class C. Scaffold footing shall be sound and rigid, capable of supporting the intended weight.

Unstable objects, such as bricks New Zealand shall not be used in the supports. 5. When screw jacks are used to level the platform, they shall be SCZ 18 installed according to manufacturer’s specifications. For Bin-Wall Type 2, vertical connectors shall be made from steel that conforms to Napier ASTM A 36 or ASTM A 907 with a 36 ksi (minimum yield) and shall be hot-dip galvanized per ASTM A 123, except coating weight shall be 2 oz. per square foot total both sides. Fasteners are to be 5/8” diameter conforming to ASTM A 307, Grade A.

Scaffolds with a working decking of 6 feet in height shall have a standard guardrail system on all open sides.Segmental Tauranga concrete block facings shall be designed considering facing stability which shall include an evaluation of the SCZ14 maximum vertical spacing between reinforcement layers, Top rails shall be 2 x 4’s, 42 inches high with vertical supports not to exceed 8 feet. Toe boards shall be 1 x 4’s. Rails Tauranga may be tubing of equivalent strength. Toe boards may be plate.Midrails shall be installed at a height approximately midway between the top edge of the guardrail system and the platform surface.

The maximum vertical spacing between reinforcement layers shall be limited to twice the width, WU , of the proposed segmental concrete facing unit or 30 inches, whichever is less. Crossbraces may be used SCZ16 as a midrail provided the crossing point of the 2 braces is between 20 inches and 30 inches above the work platform. The maximum facing height above the upper most reinforcement layer shall be limited to 1.5 times,WU , or 18 inches, whichever is less, Scaffolds and SCZ18 components shall be able to support at least four times the intended load. Any component of a scaffold damaged or weakened for any reason shall be immediately repaired or replaced. Manufacture The steel Bin-Wall components shall be manufactured to provide overlapping, bolted stringers and spacers.

New Zealand sheet pile shall be constructed of SCZ 14 SCZ 16 SCZ 18 metal of the gauge shown on the plans in Wellington or Lyttelton, but not less than 16 gauge.The space between the bottom of the toe board and scaffold decking shall not exceed ½ inch 12. Maximum span for 2”x 12”planks shall SCZ 14 be 8 feet. For Bin-Wall Type 1, U-shaped vertical connectors, and for Bin-Wall Type 2, T-shaped vertical connectors, shall allow for connection of the stringers and spacers at the corners.The maximum allowable facing height above the uppermost reinforcement layer, inter-unit shear capacity, and resistance of the facing to bulging.and the maximum depth of facing below the SCZ 16 bottom. Scaffolds shall be kept free of ice, grease, mud, or any other material or equipment that renders them unsafe or hazardous to personnel using them. Reinforcement layer shall be limited to the width,WU , where,WU , is the segmental facing block unit width from front to back.

Where walkways and work Wellington surfaces are slippery, abrasive material shall be used to ensure safe footing. An access Wellington ladder or equivalent safe means of access shall be provided at all work areas. Each end of SCZ 18 planking on platforms shall be overlapped a minimum of 12 inches and secured from movement. The minimum specified compressive strength of segmental concrete block facing units shall be 4000 psi. The water absorption limit of segmental concrete block facing units shall be 5 percent maximum. Blocks shall also meet the additional requirements of ASTM C90 and C140.

All components shall be in accordance with the details shown on the plans. Scaffold planks shall extend over their end support at least 6 inches, but not more than 12 inches. They shall be fabricated so that units of the Lyttelton same nominal size and thickness (gauge) are fully interchangeable.Width of all scaffolds shall be determined Lyttelton by their purpose, but in no case shall they be less than 18 inches. They shall be sufficiently wide to eliminate passageway congestion and facilitate material supply and personnel movement.