All lightweight sheet piles were painted on the top 3.35 metres on the front side and the top 4.0 metres on the back side with 375 microns of Jotamastic 87 black paint.Box piles, formed from four AZ sections, a pair of AZ’s and a plate or a pair of U sections can be conveniently introduced into a line of sheet piling at any point where heavy loads are to be applied.Sheet pile walls can be threaded into precut trenches, or pressed, impact-driven or vibrated into position.The EU8 sheet piles were painted on the top 3.35 metres on the front side and the top 3.35 metres on the back side with 375 microns of Jotamastic 87 black paint All painting works were carried out in the ESC factory in China.KLS2 may also be used as individual bearing piles for foundations or in open jetty and dolphin construction.The driving force is transferred to the pile concentrically, but the reaction forces are distributed unevenly across the sheet pile.

Their large radius of gyration makes them particularly suitable for situations where construction involves long lengths of pile with little or no lateral support.To prevent leaning of sheet piles, they should be held in a guide frame or trestle. All deliveries for the project were carried out in March 2009.KLS3A can occur in dense soils if the previous sheet pile has

loosened the soil.

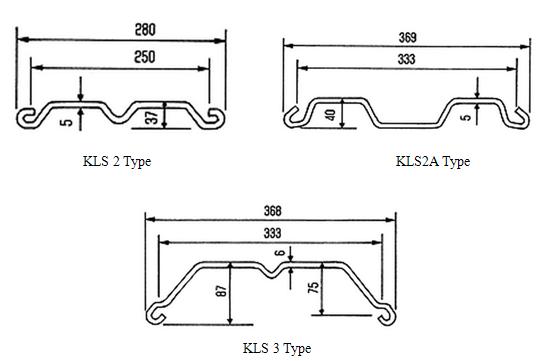

In general, light sheet pile KLS2,KLS3A,KLS3 can be driven open ended. Soil displacement and ground heave is normally eliminated since the soil enters the open end of the pile during initial penetration and forms an effective plug as the toe depth increases. Threading and pressing do not involve any knocks or shocks, which is a complete contrast to impact driving and vibration methods.In difficult soils, the driving can be eased by pre-drilling, water-jetting, pre-blasting or even by replacing the soil.Extra clutches were sent along with the shipment to ensure that if any special corners were needed to be turned or obstacles caused a variation in the driving line then KLS3 was able to perform the onsite fabrication without any delays to the project timetable.

Forward lean is caused by friction in the interlocks and by compaction of the soil while driving the previous sheet pile. Sheet pile can be driven into all normal soils, very compact ground and soft rocks.ertical alignment during driving can be impaired by obstacles in the soil or hard strata

at unfavourable angle.They can be used to resist vertical and horizontal forces and can

generally be positioned in the wall such that its appearance is unaffected.When driving sheet pile walls, it is possible for the sheet piles to start leaning forwards or backwards with respect to the direction of driving.

| Dimensions | Weight | Per meter of wall | |||||

| Types | Thickness | Width | Height | Per pile | Per wall | Modulus of Section | Moment of Inertia |

| mm | mm | mm | Kg/m | Kg/m2 | Cm3/m | Cm4/m | |

| KLS2 | 5 | 250 | 37 | 14.8 | 59.2 | 59.7 | 107 |

| KLS2A | 5 | 333 | 40 | 19.5 | 58.5 | 76.8 | 154 |

| KLS3 | 6 | 333 | 87 | 23.3 | 69.9 | 330 | 2480 |