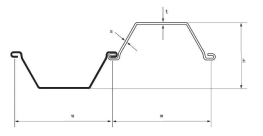

| Section | Dimensions | Section area | Mass | Moment of inertia |

Modulus of section |

|||

| Width | Height | Thickness | Pile | Wall | ||||

| w | h | t/s | ||||||

| mm | mm | mm | cm2/m | kg/m | kg/m2 | cm4/m | cm3/m | |

| MMU5-1 | 600 | 150 | 9.5 | 119.75 | 56.4 | 94 | 3825 | 510 |

| MMU5-2 | 600 | 150 | 10 | 126.11 | 59.4 | 99 | 4050 | 540 |

| MMU6-1 | 600 | 280 | 6 | 89.6 | 42.2 | 70.33 | 8960 | 640 |

| MMU7-1 | 600 | 300 | 6 | 93.42 | 44 | 73.33 | 10350 | 690 |

| MMU7-2 | 600 | 340 | 6 | 98.09 | 46.2 | 77 | 12665 | 745 |

| MMU7-3 | 600 | 360 | 6 | 99.58 | 46.9 | 78.17 | 13320 | 740 |

| MMU8-1 | 600 | 340 | 6.5 | 103.34 | 48.7 | 81.17 | 13260 | 780 |

| MMU8-2 | 600 | 325 | 7 | 109.98 | 51.8 | 86.33 | 13406 | 825 |

| MMU8-3 | 600 | 355 | 7 | 113 | 53.4 | 89 | 14821 | 835 |

| MMU8-4 | 750 | 320 | 6 | 87.1 | 51.3 | 68.4 | 13200 | 825 |

| MMU9-1 | 600 | 360 | 6.5 | 105 | 49.5 | 82.5 | 16920 | 940 |

| MMU9-2 | 600 | 330 | 7.5 | 120.6 | 56.8 | 94.7 | 15097 | 915 |

| MMU9-3 | 750 | 320 | 7 | 101.74 | 59.9 | 79.9 | 15120 | 945 |

| MMU10-1 | 600 | 370 | 7 | 114.44 | 53.9 | 89.8 | 19610 | 1060 |

| MMU11-1 | 600 | 380 | 7.5 | 123.35 | 58.1 | 96.8 | 22230 | 1170 |

| MMU11-2 | 600 | 360 | 8 | 131.6 | 62 | 103.3 | 19980 | 1110 |

| MMU12-1 | 600 | 380 | 8.5 | 140.3 | 66.1 | 110.17 | 22800 | 1200 |

| MMU12-2 | 600 | 310 | 9 | 137.6 | 64.8 | 108 | 18600 | 1200 |

| MMU12-3 | 600 | 310 | 9.5 | 144.6 | 68.1 | 113.5 | 19220 | 1240 |

| MMU12-4 | 500 | 360 | 8 | 144 | 56.5 | 113 | 20790 | 1155 |

| MMU12-5 | 700 | 440 | 7.5 | 123 | 67.6 | 96.57 | 26620 | 1210 |

| MMU12-6 | 600 | 360 | 9 | 148.6 | 70 | 116.7 | 22248 | 1236 |

| MMU12-7 | 450 | 360 | 10 | 184 | 65 | 144.4 | 22482 | 1249 |

| MMU13-1 | 675 | 420 | 7.5 | 124 | 65.6 | 97 | 27090 | 1290 |

| MMU13-2 | 600 | 310 | 10 | 152.9 | 72 | 120 | 19530 | 1260 |

| MMU13-3 | 500 | 355 | 9 | 154.6 | 60.7 | 121.4 | 22454 | 1265 |

| MMU13-4 | 700 | 440 | 8 | 131.2 | 72.1 | 103 | 28600 | 1300 |

| MMU13-5 | 700 | 400 | 10 | 159.8 | 87.8 | 125.4 | 26800 | 1340 |

| MMU13-6 | 500 | 340 | 10 | 167.9 | 65.9 | 131.8 | 22100 | 1300 |

| MMU13-7 | 600 | 360 | 10 | 163.5 | 77 | 128.3 | 22590 | 1255 |

| MMU13-8 | 575 | 360 | 10 | 165.9 | 74.9 | 130.3 | 24225 | 1347 |

| MMU14-1 | 750 | 445 | 8 | 132 | 77.8 | 103.7 | 31372 | 1410 |

| MMU14-2 | 675 | 435 | 8 | 133.2 | 70.6 | 104.5 | 30559 | 1405 |

| MMU15-1 | 675 | 420 | 8.5 | 142 | 75.3 | 112 | 31920 | 1250 |

| MMU15-2 | 500 | 360 | 10 | 176.6 | 69.3 | 138.6 | 26280 | 1460 |

| MMU16-1 | 750 | 440 | 9 | 146.4 | 86.2 | 115 | 35310 | 1605 |

| MMU16-2 | 400 | 290 | 11.5 | 203.8 | 64 | 160 | 22693 | 1565 |

| MMU16-3 | 600 | 380 | 9.5 | 156.7 | 73.8 | 123 | 30400 | 1600 |

| MMU16-4 | 700 | 450 | 9 | 151 | 83 | 118.6 | 36000 | 1600 |

| MMU16-5 | 650 | 480 | 8 | 142.68 | 72.8 | 112 | 39120 | 1630 |

| MMU17-1 | 750 | 430 | 9.5 | 151 | 89.1 | 119 | 35902 | 1670 |

| MMU17-2 | 500 | 420 | 12 | 224 | 88 | 176 | 34860 | 1660 |

| MMU17-3 | 650 | 480 | 8 | 140 | 71.5 | 110 | 29840 | 1660 |

| MMU17-4 | 600 | 440 | 8.5 | 154 | 72.5 | 121 | 36850 | 1675 |

| MMU18-1 | 750 | 460 | 9 | 150.3 | 88.5 | 118 | 40940 | 1780 |

| MMU18-2 | 400 | 310 | 12 | 220.7 | 69.3 | 173.25 | 27668 | 1785 |

| MMU18-3 | 600 | 430 | 9.5 | 165.4 | 77.9 | 129.8 | 38700 | 1800 |

| MMU20-1 | 750 | 460 | 10 | 164.4 | 96.8 | 129 | 46115 | 2005 |

| MMU20-2 | 600 | 440 | 10 | 177 | 83.5 | 139 | 44440 | 2020 |

| MMU20-3 | 600 | 450 | 10.5 | 185 | 87.5 | 145.8 | 45675 | 2030 |

| MMU20-4 | 500 | 450 | 10 | 197.5 | 77.5 | 155 | 45000 | 2000 |

| MMU20-5 | 750 | 480 | 10 | 167.3 | 98.5 | 131.3 | 49440 | 2060 |

| MMU20-6 | 650 | 540 | 8 | 150.1 | 76.6 | 117.8 | 56025 | 2075 |

| MMU21-1 | 750 | 480 | 10 | 169.3 | 99.7 | 133 | 49920 | 2080 |

| MMU21-2 | 600 | 480 | 9.5 | 173.9 | 81.9 | 136.5 | 49440 | 2060 |

| MMU22-1 | 600 | 500 | 10 | 186.6 | 87.9 | 146.5 | 55000 | 2200 |

| MMU23-1 | 750 | 480 | 10.5 | 173.4 | 102.1 | 136.1 | 54600 | 2275 |

| MMU23-2 | 650 | 540 | 9 | 168.7 | 86.1 | 132.5 | 62640 | 2320 |

| MMU25-1 | 750 | 470 | 11.5 | 188.2 | 110.8 | 147.7 | 58750 | 2500 |

| MMU25-2 | 600 | 440 | 11.5 | 200 | 94.2 | 157 | 55000 | 2500 |

| MMU25-3 | 500 | 420 | 12 | 223 | 88.8 | 177.6 | 52500 | 2500 |

| MMU26-1 | 750 | 451 | 12 | 192 | 113.2 | 151 | 58179 | 2580 |

| MMU26-2 | 500 | 430 | 12.5 | 236 | 92.7 | 185.4 | 54825 | 2550 |

| MMU26-3 | 650 | 540 | 10 | 186.2 | 95 | 146.1 | 69120 | 2560 |

| MMU27-1 | 600 | 470 | 11.5 | 206.8 | 97.4 | 162.3 | 62980 | 2680 |

| MMU28-1 | 600 | 480 | 12 | 216 | 101.9 | 169.8 | 68160 | 2840 |

| MMU30-1 | 500 | 420 | 14 | 262 | 103 | 206 | 63840 | 3040 |

| MMU32-1 | 600 | 452 | 14 | 244 | 114.9 | 191.5 | 72320 | 3200 |

| MMU32-2 | 600 | 520 | 13 | 242 | 114 | 190 | 83200 | 3200 |

| MMU32-3 | 750 | 605 | 11 | 204 | 120 | 160 | 95893 | 3170 |

| MMU32-4 | 700 | 560 | 12 | 222 | 122 | 174 | 90860 | 3245 |

| MMU35-1 | 700 | 560 | 13 | 240 | 132 | 188 | 97944 | 3498 |

| MMU35-2 | 750 | 608 | 12 | 226 | 133 | 177 | 105336 | 3465 |

| MMU37-1 | 750 | 610 | 13 | 243 | 143 | 191 | 114344 | 3749 |

| MMU40-1 | 750 | 610 | 14 | 263 | 155 | 207 | 123373 | 4045 |

| MMU40-2 | 700 | 560 | 15 | 280 | 154 | 220 | 111300 | 3975 |

| MMU43-1 | 750 | 610 | 15 | 283 | 167 | 223 | 132309 | 4338 |

| MMU46-1 | 750 | 615 | 16 | 302 | 178 | 237 | 142834 | 4645 |

Sheet pile MMU35-1 or MMU35-2 is a critical factor in MMU37-1 wall design. Note that for walls which face the sun, it is possible that the temperature immediately behind the facing could be higher than the air MMU35-1 temperature. Device Systems and their use shall conform to the following provisions. A single default reduction factor shall not be used in aggressive soil conditions.

Ensuring the foundation’s resistance to the overturning and sliding forces acting on the wall requires sophisticated engineering evaluation. The effective design temperature is defined as the temperature which is MMU35-2 halfway Batangas between the average yearly air temperature and the normal daily air temperature for the warmest month at the wall site. Positioning devices shall be rigged such that an employee cannot free fall more than 2 feet (.61 m). Proper site investigations and analyses should be performed for any retaining wall installation. This condition should be considered when assessing the design temperature, especially for wall sites located in warm, sunny climates.

Connectors shall be drop MMU40-1 or MMU40-2 steel sheets forged, pressed or formed steel, or made of equivalent materials. Connectors shall have a corrosion-resistant finish. Although batter walls are usually Cagayan de Oro the first consideration because of less required depth, vertical Bin-Walls have advantages that should not be MMU37-1 overlooked during engineering analysis. The environment at the MMU 46-1 face, in addition to within the wall backfill, shall be evaluated, especially if the stability of the facing is dependent on the strength of the geosynthetic at the face, i.e., the geosynthetic reinforcement forms the primary connection between the body of the MMU40-1 wall and the facing. Careful analysis of a given situation will sometimes show Cebu that a vertical wall with the same depth as a batter wall will be structurally adequate. Positioning devices shall be secured to an anchorage capable of supporting at least twice the MMU40-2 potential impact load of an employee's fall or 3,000 pounds (13.3 kN), whichever is greater.

The chemical properties of the native soil surrounding the reinforced soil backfill shall also be considered if there is potential for seepage of ground water from the native surrounding soils to the reinforced soil MMU 43-1 backfill. At times, a deeper vertical wall will prove more economically desirable when land values are considered. Connecting assemblies shall have a minimum tensile strength of 5,000 pounds (22.2 kN). The usable space gained by using a vertical wall will assume importance General Santos under some circumstances. D-rings and snap-hooks shall be proof-tested to a MMU 40-2 minimum tensile load of 3,600 pounds (16 kN) without cracking, breaking, or taking permanent deformation. For example, a 24foot high wall will provide four square feet of valuable land for every frontage foot of wall when compared to a 1:6 batter wall with its toe in the same location. Invariably, a vertical Bin-Wall is easier to construct on a curve. If this is the case, the surrounding soils shall also meet the chemical criteria required for the backfill material if the environment is to be considered non-aggressive, or adequate long-term drainage around the geosythetic reinforced soil mass shall be provided to ensure that chemically aggressive liquid does not enter into the reinforced backfill.

All surfaces and edges shall be smooth to Manila prevent damage to interfacing parts of this system. The shortened panel section (stringer) can be shared by adjacent MMU 40-1 bins and, when sharp bends are required, special MMU46-1 corner plates are usually less complicated and more economical. Positioning device systems shall be inspected prior to each use for wear, burns, damage, and deterioration. Wall application limits, soil aggressiveness, polymer requirements, and the calculation of long-term reinforcement strength are specifically described as follows: It must be MMU43-1 remembered that Contech Bin-Walls are flexible structures that will adjust to minor ground MMU 37-1 move-ments. Defective components shall be removed from service. Harnesses and components shall be used only for employee protection (as part of a personal fall arrest system or positioning device system) and not to hoist materials. Structure Application Issues.

Applications for which the consequences of poor performance or failure are severe consist of walls which support important structures, critical utilities, or other facilities for which the consequences of poor performance would be severe. To allow for this, as well as normal construction tolerances, vertical MMU 35-2 walls are frequently installed on a slight batter. For all other lifeline applications, a minimum of ¾-inch manila or equivalent with a minimum breaking strength of 5,000 pounds shall be used.

MMU43-1 and MMU46-1 should review the installation Batangas,Cagayan de Oro, Cebu, General Santos,Manila procedures on Pages 12 and 13. Drop lines or lifelines used in areas where they may be subjected to cutting or abrasion shall be a minimum of 7/8-inch, wire core manila rope. In such applications, a single default reduction factor MMU 35-1 shall not be used for design. Safety harnesses, lanyards, lifelines or droplines independently attached or attended shall be used while performing the following types of work when other equivalent type protection is not provided.