There are many advantages to constructing with taper flange beams.The Structural Engineer must design the steel members and give guidelines for the connections.Some structural steel shapes such as I-beams have a high second moments of area, which can result in stiffness compared to cross-sectional area.The cold-formed sections are suitable for all types of welding such as spot welding, seam welding, projection welding, butt and groove welding, plug welding and arc welding. It is very important for engineers to have understanding of the taper flange columns.

The strength to weight ratio is excellent; metals join easily; efficient shapes are available; etc. All of these are applicable to both uncoated and zinc coated British joists with taper flanges. Most structural steel failures occur at connections, where a beam connects to a taper flange column, where a joist connects to a beam, etc.For example they are used in, building frames, roof trusses, floor framing, bench frames, gates, fences, cattle grids, scaffolds, tank stands, television towers, car trailers, rails, etc.

Different shapes of structural steel (both hot-rolled and cold-formed) are available with specifications such as: I-beam’s, Z-Shape (half a flange in opposite directions), HSS-Shape (Hollow structural section such as square, , Channel ( [-shaped), Tee (T-shaped cross-sections).These advantages create challenges that are best solved by a good understanding of how the metals actually perform in a structure. Taper flange beam shapes are suitable for a wide variety of uses.

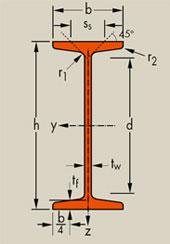

Dimensions:

BS 4-1: 2005

Tolerances:

EN 10024: 1995

Surface condition:

According to EN 10163-3: 2004, class C, subclass 1

| Designation | Mass per m |

Depth of Section |

Width of Section |

Thickness of | Root Radius |

Toe Radius |

Flange Taper |

|

| M | h | b | (web)s | (flange)t | r1 | r2 | a | |

| kg/m | mm | mm | mm | mm | mm | mm | Degrees | |

| 254x203x82 | 82 | 254 | 203,2 | 10,2 | 19,9 | 19,6 | 9,7 | 8 |

| 254x114x37 | 37,1 | 254 | 114,3 | 7,6 | 12,8 | 12,4 | 6,1 | 8 |

| 203x152x52 | 52,2 | 203,2 | 152,4 | 8,9 | 16,5 | 15,5 | 7,6 | 8 |

| 152x127x37 | 37,2 | 152,4 | 127 | 10,4 | 13,2 | 13,5 | 6,6 | 8 |

| 127x114x29 | 29,3 | 127 | 114,3 | 10,2 | 11,5 | 9,9 | 4,8 | 8 |

| 127x114x27 | 26,8 | 127 | 114,3 | 7,4 | 11,4 | 9,9 | 5 | 8 |

| 127x76x16 | 16,5 | 127 | 76,2 | 5,6 | 9,6 | 9,4 | 4,6 | 8 |

| 114x114x27 | 27 | 114,3 | 114,3 | 9,5 | 10,7 | 14,2 | 3,2 | 8 |

| 102x102x23 | 23 | 101,6 | 101,6 | 9,5 | 10,3 | 11,1 | 3,2 | 8 |

| 102x44x7 | 7,4 | 101,6 | 44,5 | 4,3 | 6,1 | 6,9 | 3,3 | 8 |

| 89x89x19 | 19,5 | 88,9 | 88,9 | 9,5 | 9,9 | 11,1 | 3,2 | 8 |

| 76x76x15 | 15 | 76,2 | 80 | 8,9 | 8,4 | 9,4 | 4,6 | 8 |

| 76x76x13 | 12,7 | 76,2 | 76,2 | 5,1 | 8,4 | 9,4 | 4,6 | 8 |