562. USES OF SHEET PILING

Sheet piling is often used in flood protection and erosion walls, due to the extreme durability and water tightness that the piles offer.

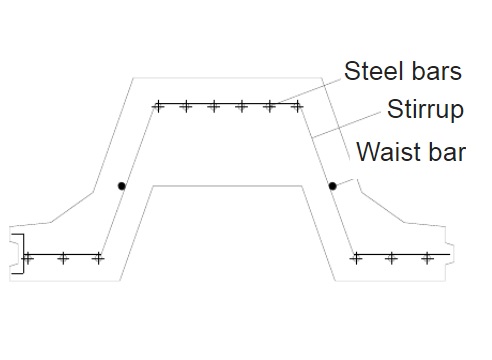

561. Construction scheme of seepage prevention sheet pile in Yaoqiao gate station

The main work of this pilot project is laying of pre-tensioned U-shaped prestressed concrete sheet piles about 550 meters in section LDX-QLSG1 of Liu-Da-Chang Waterway Regulation Project. Pre-tensioned U-shaped prestressed concrete sheet piles made of concrete and having a generally U-shaped cross-section

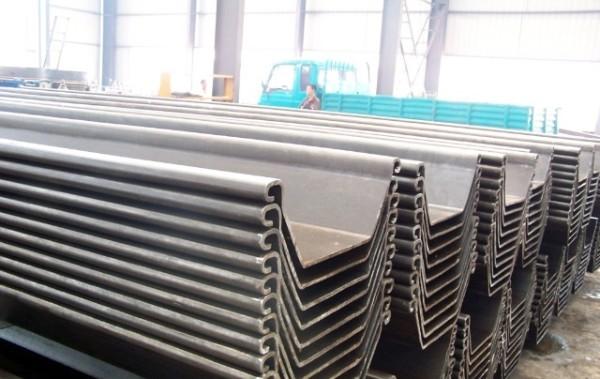

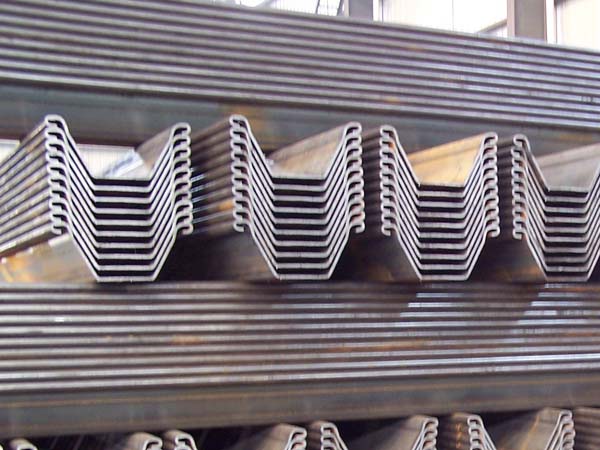

560. Six applications of steel sheet pile

China is emerging sheet pile heat, whether it is hot-rolled AZ or cold bend U-type, are sought after in the market. Here are 6 apps you may use in your building project!

559. Small vibration, low noise static pressure steel sheet pile construction process

Deputy General Manager Fang Yajie told reporters that the basement construction has been using small vibration, low noise static pressure steel sheet pile construction technology to carry out The construction of foundation pit support effectively avoids the impact of construction vibration on the adjacent buildings and the interference of noise on the normal life of surrounding residents.

558. The definition and application of steel sheet pile

Steel sheet pile is a kind of edge linkage device, and the linkage device can be combined freely to form a continuous and tight steel structure of retaining wall or retaining wall.

557. Larsen steel sheet pile price analysis how much Larsen steel sheet pile high efficiency

Larsen sheet pile in the construction, is the buckle lap composition of steel sheet retaining wall, sealing effect is good, close contact between the two piles, high strength. Commonly used length of 9 meters, 12m, 15m and 18m. Can adapt to any depth of the pit construction, short construction period, construction convenience, stability. In the construction of the foundation pit can be completed after filling the steel sheet pile has been prepared for re-use.

556. Flat sheet piles work differently from other sheet piles

Flat web sheet piles work differently from other sheet piles. Most sheet piles rely on their bending strength and stiffness to retain the soil or water.

555. Types and advantages and disadvantage of steel sheet pile driver

Steel sheet pile in China more and more practical, so driven steel sheet pile driver development, then we come to the following popular steel sheet pile knowledge.

554. Sheet Pile Support System Inspection and Remediation

In order to restore strength lost by the damaged walers, our engineering team designed a belt system consisting of two wide flange beams welded to the structurally sound sheet piling.

553. Design of steel sheet pile installation by vibration

In this paper a new design equation is presented, which consists of three parts: the mass of the sheet pile, the friction along the shaft and the soil resistance at the tip of the pile based on the cone penetration resistance.

552. Sheet Pile Retaining Walls

Once our sheet pile retaining walls are installed, excavation works can commence immediately, negating the need for any curing period that is normally required for alternative secant and contiguous pile walls.

551. Concrete piles vs steel piles

Steel Piles carry relatively small cross-sectional area and are suitable for handling and driving in long lengths.

550. Welded Pipes Manufacturing Processe

Less thickness pipe, mainly ERW / EFW or HFW welded pipes are formed by continues rolling method.

548. CP1 and CP2 Corner Piles for Sheet Piling

Both CP1 and CP2 provides excellent time and cost savings to your job site by being able to quickly deploy corner piles in a safe and efficient manner.

547. What Is Pultruded Sheet Piling?

Unlike most vinyl sheet piling which is simply a non-reinforced pvc (poly vinyl chloride) extruded into the shape of an interlocking sheet pile configuration, pultruded sheet piling is a fiber reinforced plastic (FRP) resin impregnated composite.

546. RTG Sheet Pile Press System

Sheet piles can be installed by static pressing with the leader mounted RTG press-system.

545. Sheet Pile Infills

For the infilling of the open pans within a sheet piling wall design installation to aid removal following construction of the associated concrete retaining wall. It provides a flat profile for the installation of a waterproof membrane.

544. Automatic Design System for a Steel Sheet Pile Cellular Cofferdam

A new design scheme has recently been introduced to a sheet pile cellular cofferdam, which takes the effect of the embedded part of a sheet pile on the structural stability into account.

543. Classification of Steel Sheet Pile Press Fit according to Structure Design

This is done by adding shorter steel sheet piles in succession or in narrow roads or rivers where large scale machines fail to approach.

542. Sheet pile cutoff wall

Sheet pile cutoff wall is used in all types of water retaining structures to reduce the exit gradient at the downstream toe and prevent the chances of sand boiling and piping.