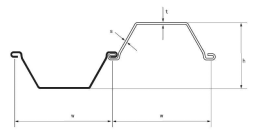

| Section | Dimensions | Section area | Mass | Moment of inertia |

Modulus of section |

|||

| Width | Height | Thickness | Pile | Wall | ||||

| w | h | t/s | ||||||

| mm | mm | mm | cm2/m | kg/m | kg/m2 | cm4/m | cm3/m | |

| MMU5-1 | 600 | 150 | 9.5 | 119.75 | 56.4 | 94 | 3825 | 510 |

| MMU5-2 | 600 | 150 | 10 | 126.11 | 59.4 | 99 | 4050 | 540 |

| MMU6-1 | 600 | 280 | 6 | 89.6 | 42.2 | 70.33 | 8960 | 640 |

| MMU7-1 | 600 | 300 | 6 | 93.42 | 44 | 73.33 | 10350 | 690 |

| MMU7-2 | 600 | 340 | 6 | 98.09 | 46.2 | 77 | 12665 | 745 |

| MMU7-3 | 600 | 360 | 6 | 99.58 | 46.9 | 78.17 | 13320 | 740 |

| MMU8-1 | 600 | 340 | 6.5 | 103.34 | 48.7 | 81.17 | 13260 | 780 |

| MMU8-2 | 600 | 325 | 7 | 109.98 | 51.8 | 86.33 | 13406 | 825 |

| MMU8-3 | 600 | 355 | 7 | 113 | 53.4 | 89 | 14821 | 835 |

| MMU8-4 | 750 | 320 | 6 | 87.1 | 51.3 | 68.4 | 13200 | 825 |

| MMU9-1 | 600 | 360 | 6.5 | 105 | 49.5 | 82.5 | 16920 | 940 |

| MMU9-2 | 600 | 330 | 7.5 | 120.6 | 56.8 | 94.7 | 15097 | 915 |

| MMU9-3 | 750 | 320 | 7 | 101.74 | 59.9 | 79.9 | 15120 | 945 |

| MMU10-1 | 600 | 370 | 7 | 114.44 | 53.9 | 89.8 | 19610 | 1060 |

| MMU11-1 | 600 | 380 | 7.5 | 123.35 | 58.1 | 96.8 | 22230 | 1170 |

| MMU11-2 | 600 | 360 | 8 | 131.6 | 62 | 103.3 | 19980 | 1110 |

| MMU12-1 | 600 | 380 | 8.5 | 140.3 | 66.1 | 110.17 | 22800 | 1200 |

| MMU12-2 | 600 | 310 | 9 | 137.6 | 64.8 | 108 | 18600 | 1200 |

| MMU12-3 | 600 | 310 | 9.5 | 144.6 | 68.1 | 113.5 | 19220 | 1240 |

| MMU12-4 | 500 | 360 | 8 | 144 | 56.5 | 113 | 20790 | 1155 |

| MMU12-5 | 700 | 440 | 7.5 | 123 | 67.6 | 96.57 | 26620 | 1210 |

| MMU12-6 | 600 | 360 | 9 | 148.6 | 70 | 116.7 | 22248 | 1236 |

| MMU12-7 | 450 | 360 | 10 | 184 | 65 | 144.4 | 22482 | 1249 |

| MMU13-1 | 675 | 420 | 7.5 | 124 | 65.6 | 97 | 27090 | 1290 |

| MMU13-2 | 600 | 310 | 10 | 152.9 | 72 | 120 | 19530 | 1260 |

| MMU13-3 | 500 | 355 | 9 | 154.6 | 60.7 | 121.4 | 22454 | 1265 |

| MMU13-4 | 700 | 440 | 8 | 131.2 | 72.1 | 103 | 28600 | 1300 |

| MMU13-5 | 700 | 400 | 10 | 159.8 | 87.8 | 125.4 | 26800 | 1340 |

| MMU13-6 | 500 | 340 | 10 | 167.9 | 65.9 | 131.8 | 22100 | 1300 |

| MMU13-7 | 600 | 360 | 10 | 163.5 | 77 | 128.3 | 22590 | 1255 |

| MMU13-8 | 575 | 360 | 10 | 165.9 | 74.9 | 130.3 | 24225 | 1347 |

| MMU14-1 | 750 | 445 | 8 | 132 | 77.8 | 103.7 | 31372 | 1410 |

| MMU14-2 | 675 | 435 | 8 | 133.2 | 70.6 | 104.5 | 30559 | 1405 |

| MMU15-1 | 675 | 420 | 8.5 | 142 | 75.3 | 112 | 31920 | 1250 |

| MMU15-2 | 500 | 360 | 10 | 176.6 | 69.3 | 138.6 | 26280 | 1460 |

| MMU16-1 | 750 | 440 | 9 | 146.4 | 86.2 | 115 | 35310 | 1605 |

| MMU16-2 | 400 | 290 | 11.5 | 203.8 | 64 | 160 | 22693 | 1565 |

| MMU16-3 | 600 | 380 | 9.5 | 156.7 | 73.8 | 123 | 30400 | 1600 |

| MMU16-4 | 700 | 450 | 9 | 151 | 83 | 118.6 | 36000 | 1600 |

| MMU16-5 | 650 | 480 | 8 | 142.68 | 72.8 | 112 | 39120 | 1630 |

| MMU17-1 | 750 | 430 | 9.5 | 151 | 89.1 | 119 | 35902 | 1670 |

| MMU17-2 | 500 | 420 | 12 | 224 | 88 | 176 | 34860 | 1660 |

| MMU17-3 | 650 | 480 | 8 | 140 | 71.5 | 110 | 29840 | 1660 |

| MMU17-4 | 600 | 440 | 8.5 | 154 | 72.5 | 121 | 36850 | 1675 |

| MMU18-1 | 750 | 460 | 9 | 150.3 | 88.5 | 118 | 40940 | 1780 |

| MMU18-2 | 400 | 310 | 12 | 220.7 | 69.3 | 173.25 | 27668 | 1785 |

| MMU18-3 | 600 | 430 | 9.5 | 165.4 | 77.9 | 129.8 | 38700 | 1800 |

| MMU20-1 | 750 | 460 | 10 | 164.4 | 96.8 | 129 | 46115 | 2005 |

| MMU20-2 | 600 | 440 | 10 | 177 | 83.5 | 139 | 44440 | 2020 |

| MMU20-3 | 600 | 450 | 10.5 | 185 | 87.5 | 145.8 | 45675 | 2030 |

| MMU20-4 | 500 | 450 | 10 | 197.5 | 77.5 | 155 | 45000 | 2000 |

| MMU20-5 | 750 | 480 | 10 | 167.3 | 98.5 | 131.3 | 49440 | 2060 |

| MMU20-6 | 650 | 540 | 8 | 150.1 | 76.6 | 117.8 | 56025 | 2075 |

| MMU21-1 | 750 | 480 | 10 | 169.3 | 99.7 | 133 | 49920 | 2080 |

| MMU21-2 | 600 | 480 | 9.5 | 173.9 | 81.9 | 136.5 | 49440 | 2060 |

| MMU22-1 | 600 | 500 | 10 | 186.6 | 87.9 | 146.5 | 55000 | 2200 |

| MMU23-1 | 750 | 480 | 10.5 | 173.4 | 102.1 | 136.1 | 54600 | 2275 |

| MMU23-2 | 650 | 540 | 9 | 168.7 | 86.1 | 132.5 | 62640 | 2320 |

| MMU25-1 | 750 | 470 | 11.5 | 188.2 | 110.8 | 147.7 | 58750 | 2500 |

| MMU25-2 | 600 | 440 | 11.5 | 200 | 94.2 | 157 | 55000 | 2500 |

| MMU25-3 | 500 | 420 | 12 | 223 | 88.8 | 177.6 | 52500 | 2500 |

| MMU26-1 | 750 | 451 | 12 | 192 | 113.2 | 151 | 58179 | 2580 |

| MMU26-2 | 500 | 430 | 12.5 | 236 | 92.7 | 185.4 | 54825 | 2550 |

| MMU26-3 | 650 | 540 | 10 | 186.2 | 95 | 146.1 | 69120 | 2560 |

| MMU27-1 | 600 | 470 | 11.5 | 206.8 | 97.4 | 162.3 | 62980 | 2680 |

| MMU28-1 | 600 | 480 | 12 | 216 | 101.9 | 169.8 | 68160 | 2840 |

| MMU30-1 | 500 | 420 | 14 | 262 | 103 | 206 | 63840 | 3040 |

| MMU32-1 | 600 | 452 | 14 | 244 | 114.9 | 191.5 | 72320 | 3200 |

| MMU32-2 | 600 | 520 | 13 | 242 | 114 | 190 | 83200 | 3200 |

| MMU32-3 | 750 | 605 | 11 | 204 | 120 | 160 | 95893 | 3170 |

| MMU32-4 | 700 | 560 | 12 | 222 | 122 | 174 | 90860 | 3245 |

| MMU35-1 | 700 | 560 | 13 | 240 | 132 | 188 | 97944 | 3498 |

| MMU35-2 | 750 | 608 | 12 | 226 | 133 | 177 | 105336 | 3465 |

| MMU37-1 | 750 | 610 | 13 | 243 | 143 | 191 | 114344 | 3749 |

| MMU40-1 | 750 | 610 | 14 | 263 | 155 | 207 | 123373 | 4045 |

| MMU40-2 | 700 | 560 | 15 | 280 | 154 | 220 | 111300 | 3975 |

| MMU43-1 | 750 | 610 | 15 | 283 | 167 | 223 | 132309 | 4338 |

| MMU46-1 | 750 | 615 | 16 | 302 | 178 | 237 | 142834 | 4645 |

Regan Industrial sheet piles MMU26-1 or MMU26-2 shall have a border MMU26-3 rope for webbing with a MMU27-1 minimum breaking strength of 5,000 pounds (22.2 kN).For harsh environments, ALUMINIZED STEEL Type 2 horizontal face sections (stringers) and transverse sections (spacers) are available depending on the required gauge. Gradation The durability of geosynthetic reinforcements is MMU26-1 influenced by environmental factors such as time, temperature, mechanical damage, stress levels, and chemical exposure (e.g., oxygen, water, andpH , which are the most common chemical factors). Safety nets shall be installed as close as practicable under the surface on MMU26-2 which employees are working, but in no case more than 30 feet (9.1 m) below such level unless specifically approved in MMU 32-4 writing by the manufacturer. Reinforced concrete face panels can usually be produced locally with various finishes. Microbiological attack may also affect certain polymers, though in general most of the polymers used for carrying load in MMU26-3 soil reinforcement applications are not affected by this. Your CONTECH Sales Engineer can provide you with more information. Safety Net Systems and their use shall MMU 32-3 comply with the following provisions. Long service CONTECH Bin-Walls can withstand temperature variations and MMU 32-3 effects of ice and snow. Safety nets shall be installed with sufficient clearance under them to prevent contact with the surface or structures below when subjected to an impact force equal to the drop-test specified.

Select granular backfill for the reinforced soil mass shall MMU 32-2 consist of material free from organic material and substantially free of shale or other soft, poor durability particles and shall not contain slag aggregate or MMU27-1 recycled materials such as glass, shredded tires, portland cement concrete rubble, asphaltic concrete rubble or other unsuitable material, and shall conform to the following MMU 32-1 requirements: Expansion and contraction caused by temperature changes are safely absorbed by MMU28-1 the all-steel construction. There is no danger of cracking. Therefore, the response of geosynthetic reinforcements to these long-term environmental factors is product specific.

Sheet piling MMU28-1 or MMU30-1 fall area to the MMU32-1 net shall be MMU32-2 unobstructed. Both the galvanized steel and ALUMIZIED STEEL Type 2 can be sprayed with field-applied coatings after erection and before backfilling. Safety nets shall extend outward from the outermost projection of the work surface as follows. The effects of these factors on product durability are dependent on the MMU30-1 polymer type used (i.e. resin type, grade, additives, and manufacturing process) and the macrostructure of the reinforcement. No obsolescence Even after years of use at one location, CONTECH Bin-Walls can be removed for use elsewhere—or they can be easily extended in length to meet changing conditions at the same site. Not all of these factors will have a significant effect on all geosynthetic products.

Except as provided, safety nets and safety net installations shall be drop-tested at the job site after initial installation and before being MMU 30-1 used as a fall protection system, whenever relocated, after major repair, and at 6-month intervals if left in one place.The Bin-Wall system is a gravity retaining wall in which an earth mass inside the bins acts as a gravity wall with the steel members holding the earth mass intact. Safety nets and their installations shall be capable of absorbing an impact MMU 28-1 force equal to that produced by the drop-test specified. These two components combine to resist soil and other superimposed loads. The drop-test shall consist of a 400-pound (180 kg) bag of sand 30 ± 2 inches (76 ± 5 cm) in diameter dropped into the net from the highest walking/working surface at which employees are exposed to fall hazards, but not from less than 42 inches (1.1 m) above that level.

However, within specific limits of wall application, soil conditions, and polymer type, strength degradation due to these factors can be anticipated to be minimal and relatively consistent from product to product, and the impact of any degradation which does occur will be minimal. This design requires adequate support for the wall under the earth mass. On rigid foundations, provision must be MMU 27-1 made for slight settlement of the vertical connector members. Even with product specific test results, RFID and RFD shall be no less than 1.1 each. When the Contractor can demonstrate that it is unreasonable to perform the drop-test as required, the Contractor (or a Competent Person) shall certify that the net and net installation are in compliance by preparing a certification record prior to the net being used as a fall protection system. For conditions which are MMU32-1 outside these defined limits (i.e. applications in which the consequences of poor performance or failure are severe, aggressive soil conditions, or polymers which are beyond the specific limits set), or if it is desired to use an overall reduction factor which is less than the default reduction factor recommended herein, then product specific MMU32-2 durability studies shall be carried out prior to use.

Regan Industrial MMU32-3 or MMU32-4 is to provide a compressible cushion under the base plates with approximately eight inches of loose fill. The most recent certification record for each net and net installation shall be available at the job site for inspection. These product specific studies shall be used to estimate the short-term and long term effects of these environmental factors on the strength and deformational characteristics of the geosynthetic reinforcement throughout the reinforcement MMU32-3 design life. Individual walls should be designed for stability according to established criteria for gravity walls, available from numerous published documents on the subject of gravity retaining wall design.

The certification record must include an identification of the net and net MMU 26-3 installation for which the certification record is being prepared. While not a substitute for specific site design, Charts A and B may be MMU 26-2 used to estimate depth-to-height ratios for gravity walls under loading conditions listed in Table 1. The Contractor MM32-4 shall inspect safety nets at least once a week for wear, damage, and other deterioration. This information, based on broad experience, is provided as a guideline only. Defective components shall be removed from service. Safety nets shall also be MMU 26-1 inspected after any occurrence that could affect the integrity of the safety net system.