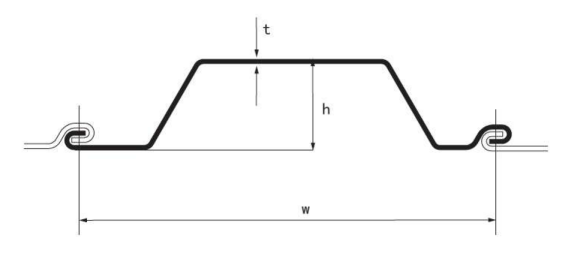

| Section | Dimensions | Sectional Area |

Mass | Moment of inertia |

Modulus of section |

|||

| Width | Height | Thickness | Pile | Wall | ||||

| w | h | t | ||||||

| mm | mm | mm | cm2/m | kg/m | kg/m2 | cm4/m | cm3/m | |

| MLL-10H | 900 | 253 | 8.3 | 122 | 86.3 | 96 | 10736 | 914 |

| MLL-25H | 900 | 350 | 9.5 | 159 | 112 | 124.5 | 29037 | 1656 |

Cold formed SSP MLL-10H and MLL-25H can quickly erect a Philippine and Singapore Bin-Wall with ordinary contractor’s equipment. Note that for walls which face the sun, it is possible that the temperature immediately behind the facing could be higher than the air temperature. There is no formwork to build, no curing delays and no followup operations. Assembling the various parts is a simple matter. All MLL-10H harnesses and lanyard hardware assemblies shall be capable of withstanding a tensile loading of 4,000 pounds without cracking, breaking, or taking a permanent deformation.

Cold formed SSP is defined as the temperature which is halfway between the average yearly air temperature and the normal daily air temperature for the warmest month at the wall site. All Contech Bin-Walls, regardless of height, are made of simple bins having a uniform basic panel length of 10 feet and varying sheet pile MLL-25H depth. This condition should be considered when assessing the design temperature, especially for wall sites located in MLL 25H warm, sunny climates. Restraint protection shall be rigged to allow the movement of employees only as far as the sides and edges of the walking/working surface. Heavier gauge stringers are used at the bottom of the wall as the height increases. Spacers are the same gauge for the entire height of transverse sections. Individual parts making up a Contech Bin-Wall are light in weight for easy handling and can be conveniently nested to save space in shipment or at the job site.The geosynthetic reinforcement forms the primary connection between the body of the wall and the facing. Rope grab devices are prohibited for fall restraint applications unless they are part of a fall restraint system designed specifically for the MLL 10H purpose by the manufacturer, and used in strict accordance with the manufacturer's recommendations and instructions.

Sheet pile MLL 10H or MLL 25H into existing ground that has adequate bearing Philippine,Singapore capacity for the completed wall loads, the earth below the normal ground line need never be disturbed. If this is the case, the surrounding soils shall also meet the chemical criteria required for the backfill MLL-10H material if the environment is to be considered non-aggressive, or adequate long-term drainage around the geosythetic reinforced soil mass shall be provided to ensure that chemically aggressive liquid does not enter into the reinforced backfill.

Trench widths and depths must be such that placing and thorough compaction of backfill can be accomplished.Defective components shall be removed from service if their function or strength is adversely MLL 25H affected.All-bolted assembly A structural wrench is the only essential tool needed to erect a Contech Bin-Wall. The environment at the face, in addition to within the wall backfill, shall be evaluated, especially if the stability of the facing is dependent on the strength of the geosynthetic at the MLL-25H face.Of course, power wrenches, hoisting equipment and other construction equipment and tools are desirable. Generally, a Contech Bin-Wall, particularly a smaller one, is erected“in place.”

Cold formed SSP reduction factor shall not be used in aggressive soil conditions. Components of fall restraint systems shall be inspected prior to each use for mildew, burns, wear, damage, and other deterioration.However, on larger projects, or where unusual working conditions are encountered, it is frequently advantageous to preassemble transverse or panel sections, partially or completely. Simple horizontal supports (such as saw horses) and power equipment will speed assembly of this major wall element.

The Contractor shall ensure component compatibility.Ordinarily, available lifting equipment can handle large transverse sections.The chemical properties of the native soil surrounding the reinforced soil backfill shall also be MLL 10H considered if there is potential for seepage of ground water from the native surrounding soils to the reinforced soil backfill.Anchorage points used for fall restraint shall be capable of supporting four times the intended load.